In today’s fast-paced and visually driven world, printing has become an essential part of communication, branding, and marketing. Whether you need business cards, brochures, banners, or custom t-shirts, choosing the right printing technique can make a significant difference in the final product’s quality and effectiveness. SpeedPrints Ghana Ltd., a leading printing service provider since 2015, offers a wide range of printing solutions tailored to meet the diverse needs of both the Ghanaian market and international clients.

This blog will take you through the various types of printing techniques, their advantages, and the best applications for each. By the end, you’ll have a comprehensive understanding of which printing method suits your specific needs, ensuring you get the best value for your investment.

- Offset Printing

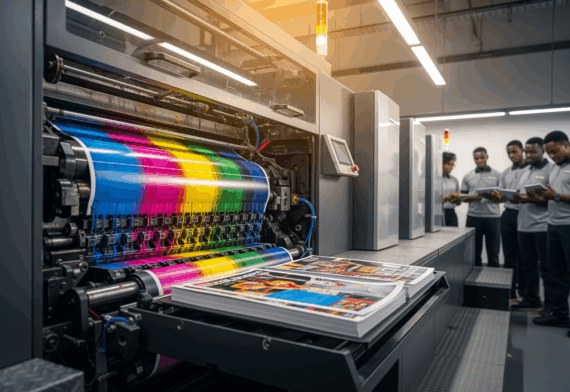

What is Offset Printing?

Offset printing is a traditional and widely used printing technique that involves transferring an inked image from a plate to a rubber blanket, and then onto the printing surface. This method is known for producing high-quality images and text, making it ideal for large-volume printing jobs.

Advantages of Offset Printing

- High-Quality Output: Offset printing delivers sharp and clean images with accurate color reproduction.

- Cost-Effective for Large Volumes: The more you print, the cheaper the cost per unit becomes, making it ideal for bulk printing.

- Versatility: It can print on a wide range of surfaces, including paper, cardboard, plastic, and metal.

- Consistency: Offset printing ensures consistent quality throughout the print run, with minimal variations.

Best Applications

Offset printing is best suited for:

- Books and Magazines: High-quality print with vibrant colors and sharp details.

- Brochures and Flyers: Professional marketing materials with consistent color and quality.

- Newspapers: Economical for large print runs with fast turnaround times.

- Digital Printing

What is Digital Printing?

Digital printing is a modern printing technique that involves printing digital images directly onto various media using inkjet or laser printers. Unlike offset printing, digital printing does not require printing plates, making it a more efficient and cost-effective option for small to medium print runs.

Advantages of Digital Printing

- Quick Turnaround: Digital printing allows for faster production times as it eliminates the need for plates and setup.

- Cost-Effective for Small Runs: Ideal for small quantities, reducing the cost per unit for shorter print runs.

- Customization: Easy to customize each print, making it perfect for personalized items like invitations or direct mail campaigns.

- On-Demand Printing: Allows for printing only what you need, reducing waste and storage costs.

Best Applications

Digital printing is ideal for:

- Business Cards: Quick and customizable, perfect for small businesses and startups.

- Posters and Banners: High-quality prints with vibrant colors for events and promotions.

- Direct Mail: Personalized marketing materials with variable data printing.

- T-Shirts and Apparel: Custom designs and short-run printing for apparel.

- Screen Printing

What is Screen Printing?

Screen Printing London is a popular printing method that involves creating a stencil (or screen) and using it to apply layers of ink on the printing surface. Each color in the design requires a separate screen, making it more suitable for designs with fewer colors.

Advantages of Screen Printing

- Durability: Screen-printed designs are long-lasting and resistant to fading, even after multiple washes.

- Vibrant Colors: This technique produces bold and bright colors, making designs stand out.

- Versatility: Can be used on a variety of materials, including textiles, glass, wood, and plastics.

- Cost-Effective for Large Runs: While setup costs are higher, the cost per unit decreases significantly with larger print runs.

Best Applications

Screen printing is best used for:

- T-Shirts and Apparel: Ideal for bold, colorful designs on clothing and accessories.

- Posters and Signs: High-impact visuals for advertising and branding.

- Promotional Items: Perfect for printing on items like bags, hats, and mugs.

- Flexography

What is Flexography?

Flexography, often referred to as flexo, is a printing process that uses flexible relief plates to transfer ink onto various substrates. It is commonly used for printing on non-porous materials like plastics, foils, and packaging materials.

Advantages of Flexography

- High-Speed Production: Flexography is one of the fastest printing methods, making it ideal for large-scale production.

- Wide Range of Substrates: Can print on almost any type of material, including paper, plastic, metal, and cellophane.

- Continuous Printing: Ideal for long runs, such as printing on rolls of material.

- Cost-Effective for Packaging: Economical for large-volume packaging printing.

Best Applications

Flexography is commonly used for:

- Packaging Materials: Ideal for printing on food packaging, labels, and cartons.

- Labels and Stickers: High-speed production for large quantities of labels.

- Newspapers: Economical for high-volume printing on a variety of paper types.

- Gravure Printing

What is Gravure Printing?

Gravure printing is an intaglio printing process where the image is engraved onto a cylinder. The engraved areas are filled with ink, and the excess ink is wiped off, leaving ink only in the recesses. The cylinder then transfers the ink onto the paper or other substrates.

Advantages of Gravure Printing

- High-Quality Output: Produces sharp, clear images with excellent color depth and detail.

- Durability: The engraved cylinders can produce millions of copies before needing replacement.

- Consistency: Maintains consistent print quality throughout large runs.

- Versatile for Long Runs: Suitable for long runs with intricate details and high-quality requirements.

Best Applications

Gravure printing is typically used for:

- High-Volume Magazines and Catalogs: Perfect for detailed images and large print runs.

- Packaging: Ideal for high-quality packaging materials, such as flexible packaging and cartons.

- Currency and Security Printing: Used for printing banknotes and other security-sensitive documents.

- DTF Printing (Direct-to-Film)

What is DTF Printing?

Direct-to-Film (DTF) printing is an innovative digital printing technique where designs are printed onto a special film and then transferred onto textiles using heat and pressure. This method is gaining popularity for its versatility and ease of use, especially in the apparel industry.

Advantages of DTF Printing

- Versatility: DTF printing works on a wide range of fabrics, including cotton, polyester, blends, and even non-fabrics.

- Vibrant and Detailed Prints: Produces high-resolution designs with bright colors and intricate details.

- Durable and Washable: The prints are long-lasting and maintain their vibrancy after many washes.

- No Need for Pre-Treatment: Unlike other textile printing methods, DTF does not require pre-treatment of fabrics.

Best Applications

DTF printing is perfect for:

- Custom Apparel: Ideal for printing on t-shirts, hoodies, and other garments with detailed and colorful designs.

- Personalized Gifts: Great for creating unique, custom items like bags, hats, and more.

- Small-Scale Production: Excellent for short runs or on-demand printing.

- Sublimation Printing

What is Sublimation Printing?

Sublimation printing is a digital printing technique that uses heat to transfer dye directly onto materials like fabric, ceramics, and metals. The dye sublimates (transforms from solid to gas) without passing through a liquid phase, embedding the color directly into the material.

Advantages of Sublimation Printing

- Permanent Prints: The colors are embedded into the material, resulting in vibrant external venetian blinds, long-lasting prints that won’t fade, crack, or peel.

- Full-Color Printing: Capable of producing a wide range of colors and intricate designs.

- Smooth Finish: The prints are smooth to the touch, as the dye becomes part of the material.

- Versatility: Works on a variety of substrates, including textiles, mugs, and phone cases.

Best Applications

Sublimation printing is ideal for:

- Custom Apparel: Especially effective for printing on polyester fabrics, producing bright, durable designs.

- Promotional Items: Perfect for printing on items like mugs, mouse pads, and phone cases.

- Home Decor: Ideal for creating custom designs on items like cushions, curtains, and wall art.

- Letterpress Printing

What is Letterpress Printing?

Letterpress printing is a traditional technique that involves pressing inked, raised letters or images onto paper. It’s one of the oldest forms of printing and is renowned for its tactile and artistic qualities.

Advantages of Letterpress Printing

- Unique Aesthetic: Produces a distinct, tactile impression on paper, adding a sense of craftsmanship and quality.

- Durability: The prints are long-lasting and resistant to wear and tear.

- Customizable: Allows for the use of different types of paper, inks, and finishes for a truly custom product.

- High Perceived Value: Often used for high-end, luxury products due to its premium look and feel.

Best Applications

Letterpress printing is best suited for:

- Invitations: Perfect for wedding invitations, greeting cards, and other special occasions.

- Business Cards: Ideal for creating high-end, professional business cards with a tactile feel.

- Stationery: Suitable for personalized stationery and notecards.

- 3D Printing

What is 3D Printing?

3D printing, also known as additive manufacturing, is a cutting-edge technology that creates three-dimensional objects by adding material layer by layer. Unlike traditional printing methods, 3D printing builds objects from the ground up based on digital designs.

Advantages of 3D Printing

- Customization: Allows for the creation of highly customized and complex designs that are difficult or impossible to achieve with traditional methods.

- Prototyping: Ideal for rapid prototyping, enabling designers to test and refine their ideas quickly.

- Material Flexibility: Can print using various materials, including plastics, metals, ceramics, and more.

- Reduced Waste: Only the necessary material is used, minimizing waste and reducing costs.

Best Applications

3D printing is perfect for:

- Prototypes and Models: Ideal for creating prototypes, architectural models, and detailed design concepts.

- Custom Parts: Useful for producing custom parts, tools, and components for various industries.

- Medical Devices: Used for creating custom medical implants, prosthetics, and other specialized equipment.

Conclusion

Understanding the different types of printing techniques is crucial in making informed decisions for your printing needs. Each method offers unique advantages and is suited for specific applications. Whether you’re looking to produce high-quality marketing materials, custom apparel, or innovative 3D models, SpeedPrints Ghana Ltd. is equipped with the expertise and technology to deliver top-notch printing solutions.

Since its inception in 2015, SpeedPrints Ghana Ltd. has been committed to providing a one-stop printing service to both the Ghanaian market and beyond. We pride ourselves on offering total flexible solutions that guarantee quality, reliability, and cost-effectiveness for all your printing needs. From digital and offset printing to cutting-edge techniques like DTF and 3D printing, we are your trusted partner in bringing your vision to life.

Contact SpeedPrints Ghana Ltd. today to explore how our wide range of printing services can meet your needs and help your business stand out in a competitive market.